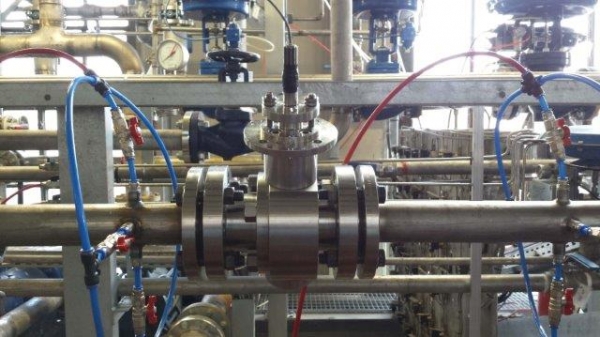

Industrial Valves

SIET is specialized in certification tests, development and characterization of all sorts of valves for industrial plants, heating, conditioning and cooling systems. Tests are carried out with different types of fluids - water, steam, gas - and, in many cases, it is possible to simulate the real valve operating conditions (up to 500 °C, 20 MPa, 200 kg/s).

Types of valves

- Isolation valves

- Control valves

- Check valves

- Safety valves

- PICV valves

- DPCV valves

Tests are carried out on valves with different design characteristics (globe valves, gate valves, ball valves, butterfly valves, etc.)

Dimensions: from DN8 (1/4") to DN500 (20")

Types of test

- Measurements of the flow coefficient (CV, KV) and recovery factor (FL) in accordance with the CEI IEC 60534-2-3 standard

- Determination of the characteristic curve (KV - travel) in accordance with the CEI IEC 60534-2-3 standard

- Determination of the discharge coefficient (K) related to the lift (h) for liquid/gas safety valves in accordance with the EN ISO 4126-1 standard

- Characterization of safety valves : UNI 11801 standard

- Leakage test with water, gas, saturated and/or superheated steam and detection of any possible leak

- Endurance tests (functional cycling) with saturated steam, water, gas

- Structural tests by using strain gages

- Vibration tests

- Thermal shock tests

- Cavitation tests by means of a specially designed innovative instrument

- Axial compressive force test, axial tensile force test, bending test

- Test on pressure independent control valve PICV

- Test on differential pressure control valve DPCV

Testing facilities: