Integral simulators of Pressurised Water Reactors

IRIS SIMULATOR

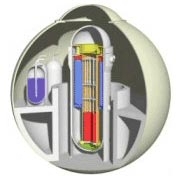

The innovative nuclear reactor IRIS (International Reactor Innovative and Secure) is developed by an international consortium including prestigious universities (Massachusetts Institute of Technology, Politecnico di Milano, Tokyo Institute of Technology...) and leading companies in the nuclear field (Westinghouse, Ansaldo, ENSA,...). IRIS is a 1000 MWt reactor, and the project is defined "safe-by-design" as the possibility of accidents is reduced, or their consequences are mitigated. The main components are contained inside the vessel, thus reducing the number of penetrations and the possibility of pipe ruptures. The containment system, much smaller than those of traditional pressurised water reactors, has been designed to resist high pressure peaks and to operate as an intrinsic safety system in case of accidents.

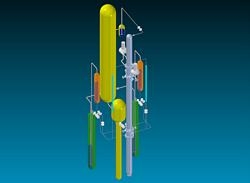

In order to carry out the tests required by NRC, the US Nuclear Regulatory Commission, an integral test facility is being planned in the SIET laboratories. It is called SPES-3 and has the following characteristics:

| volumetric scaling | 1:100 |

| elevation scaling | 1:1 (total height ~25 m) |

| power | 6.5 MW |

| design pressure | 17.5 MPa |

| power channel rod number | 235 |

| steam generators | prototypical helical coil tubes |

| primary pump | 1 external pump |

| pressurizer | integrated with spray and heating rods |

The following systems will be simulated: primary loop, secondary loop up to the main steam isolation valves, safety systems and, for the first time in an integral test facility, the containment. It is expected that about 15 accidental transients will be carried out, mostly of the SBLOCA (Small Break Loss of Coolant Accident) type.

1999, SPES 99 CAMPAIGN

In 1999 the SPES simulator was used again to carry out a new test (10"- IBLOCA) on a particular configuration of the facility without passive safety systems.

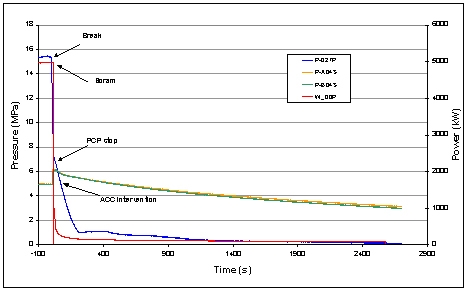

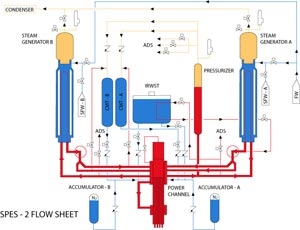

1992/1994, SPES-2 CAMPAIGN

reactor simulated: W AP600

principal tests carried out: 15 transients (SBLOCA, SG tube rupture...)

customers: Westinghouse, ENEA, ENEL

principal aims:

- certification and granting of the NRC (US Nuclear Regulatory Commission) licensing

- verification of the passive safety systems operation

- assessment of thermo-hydraulic codes (RELAP)

1988/91, SPES-1 CAMPAIGN

reactor simulated: PWR W 312

principal tests carried out:

- small break LOCAS (counterpart tests with France, Italy and Japan)

- station blackout

- loss of feed water (International Standard Problem ISP 22)

- circolazione naturale

principal customer: ENEA

principal aims:

checking the behaviour of the reactor after an accident and the consequent assessment of numerical safety codes.

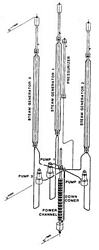

SPES PLANT

SPES is an experimental facility simulating the primary loop of a PWR (Pressurized Water Reactor). This facility maintains the same height ( ~ 30 m) of the reference nulear power plant, while the volume and power are scaled 1:400. The facility has all the devices to simulate and study the behaviour of a nuclear power plant both during operational and accidental transients. Power (~ 7 MW) is supplied by joule effect by means of a hundred rods of the same size as the real ones. This experimental facility, called SPES (Simulatore Pressurizzato per Esperienze di Sicurezza - Pressurised Simulator for Safety Experiments), may be considered, on account of its size and the power supplied, unique in the world, and has been used for experimental programmes in collaboration with prestigious international organisations.